Product type:

KME Magnetic Lifting

Permanent magnet made of Neodymium. Rated with a safety factor of 3

| Type | WLL Flat Plate (kg) | WLL Round Bar (kg) | Weight (kg) |

|---|---|---|---|

| Type | WLL Flat Plate (kg) | WLL Round Bar (kg) | Weight (kg) |

| KME 100 | 100 | 30 | 3 |

| KME 300 | 300 | 100 | 11 |

| KME 600 | 600 | 200 | 24 |

| KME 1000 | 1000 | 300 | 50 |

| KME 2000 | 2000 | 600 | 90 |

KME Dimensions

| Type | L (mm) | B (mm) | H (mm) | R (mm) |

|---|---|---|---|---|

| Type | L (mm) | B (mm) | H (mm) | R (mm) |

| KME 100 | 130 | 64 | 73 | 157 |

| KME 300 | 201 | 93 | 94 | 212 |

| KME 600 | 258 | 120 | 117 | 228 |

| KME 1000 | 310 | 130 | 140 | 255 |

| KME 2000 | 500 | 185 | 185 | 450 |

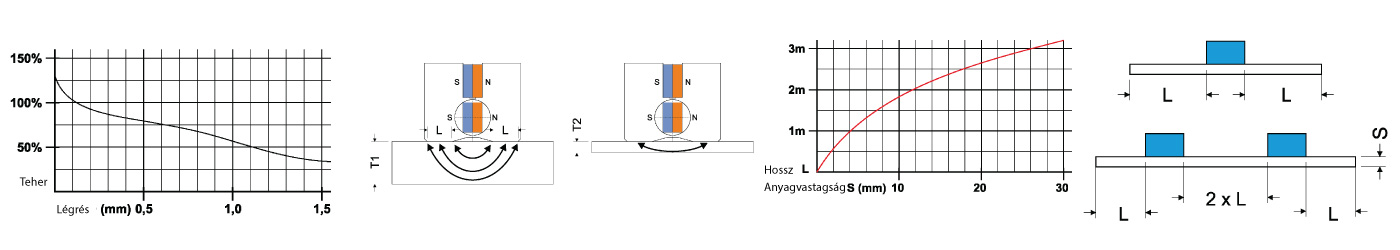

Not every load with ferromagnetic properties can safely be handled with a magnetic lifter. The magnetic lifter selected must match the characteristics of the load. As well as the weight, this includes the shape, surface finish and magnetic properties of the load.

For long loads, an arrangement of several magnets used in conjunction with a lifting beam is generally suitable as it provides the load with adequate support along its length. The position and capacity of the individual magnets should be such as to ensure that the share of the load imposed on each does not exceed its working load limit.

For flexible loads, the positioning should provide support at short enough spaces to prevent the load from peeling off the magnet.

Lifting magnets are normally rated for lifting a horizontal load in the vertical plane only. If the line of pull is not at right angles to the plane of the load, their lifting capacity will be substantially reduced and slippage may occur.

Below some data to the capacity-changes depending on the gap between load and magnet or the thickness of the material to be lifted: